1. Corrosion-resistant coating

2. Provides a secure and reliable hold

3. Durable and impact-resistant construction

4. Enhanced slip resistance with self-lock feature

5. Improved grip prevents slippage during transport

6. Tighter closure design for improved effectiveness

7. Customisation available for different sizes and designs

8. Suitable for outdoor and maritime environments

Phosphated Steel Wire Buckle

- Surface

- Size

Description

Phosphate Wire Buckles are used in composite strapping and lashing applications. The wire buckles provide a robust linkage with Polyester strapping and ensure a secure and tight grip on loads during transportation.

Enhanced Corrosion Resistance

The surface coating of the Phosphate Wire Buckles improves the friction between the buckle and the strapping material, resulting in a stronger grip. This enhanced grip prevents the strapping from slipping or loosening during transit and assures a stable and secure hold on the cargo.

Innovative "Self-Lock" Mechanism

Our Phosphorus Wire Buckles also feature a unique “self-lock” mechanism that exhibits excellent slip resistance and enhances their capacity to maintain grip. Each wire buckle is designed with a small dent or W-shaped contour on the corner of the tensioning side to facilitate a more secure closure.

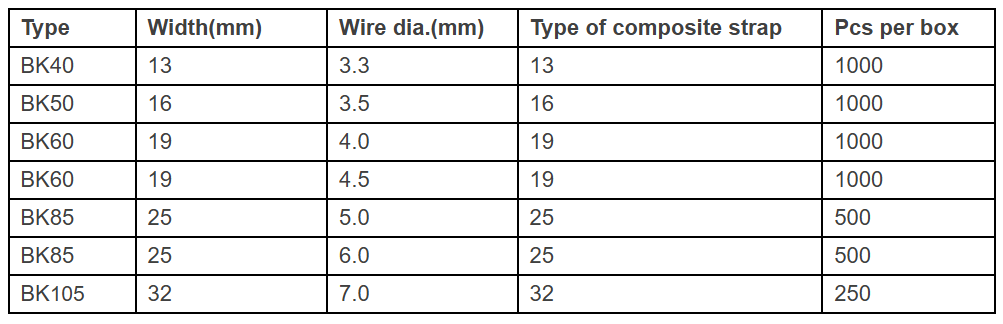

Specification

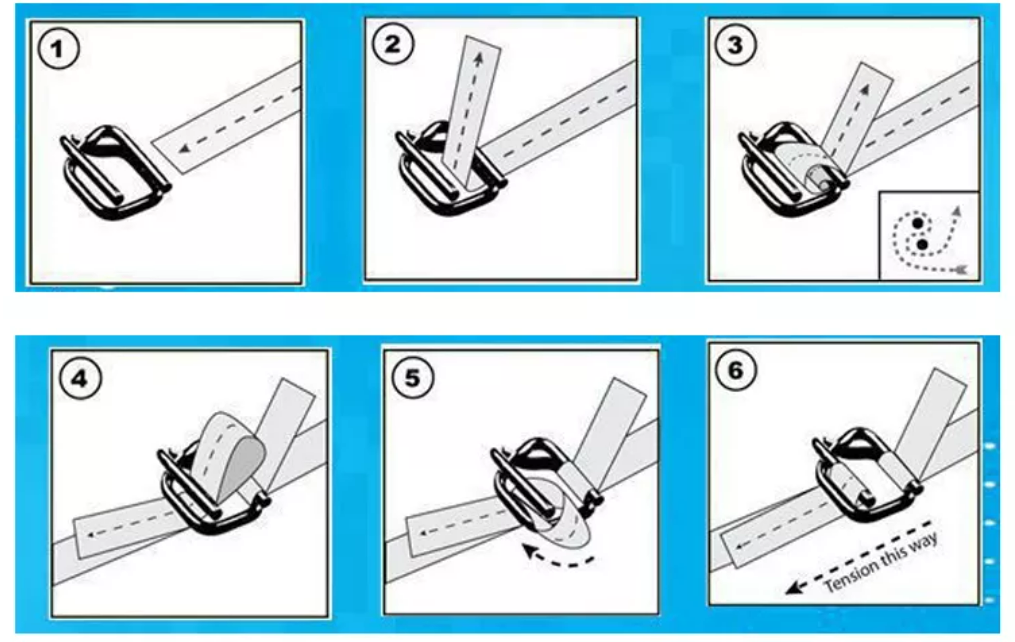

Usage Guide